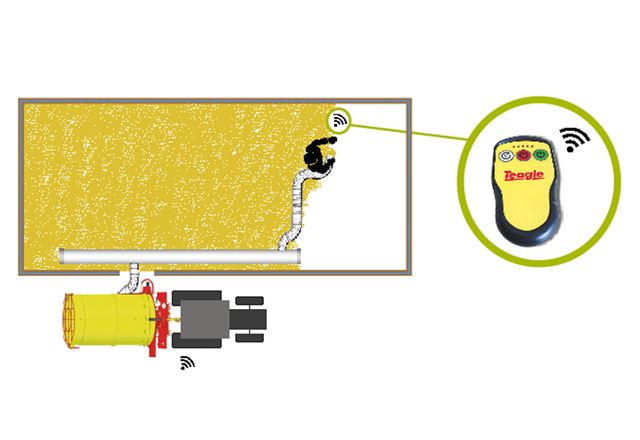

The Tomahawk Turbo Mill allows for the processing of material outside and distribution inside, promoting increased biosecurity. A quick-fit connection to the Tomahawk outside facilitates the spreading of bedding material using a flexible tube or fixed manifold system. This minimises livestock disturbance and reduces the risk of bio-contamination. To operate, load the bale into the Tomahawk Turbo Mill, start the tractor PTO, and engage the direct drive to the mill rotor. The onboard pump provides hydraulic power to the booster fan. This system is designed to process and distribute baled material with a moisture content of up to 20%. The operator, equipped with a wireless link to the hydraulic valve, can control the drum rotation and discharge from any location. Selecting the appropriate screen in the mill (10mm – 50mm) allows the production of the desired material length. Engaging the tractor PTO activates the high-speed turbo fan, delivering processed material at a rapid rate. The high-speed fan can be connected to various delivery systems, such as a 127mm (5″) diameter pipe/manifold.

Teagle Tomahawk 500B

- New in stock

- Used in stock

- Available to order

- Remote Distribution – the high speed turbo fan makes it possible to send finely chopped straw in a pipe of 127mm diameter up to 80m

- Remote Control – from up to 100m away from the tractor enables the operator to start/stop the flow of the straw

- Knife System – for high feed rate, use only with screen sizes greater than 12mm

- Process – Engage the tractor PTO and the high speed turbo fan delivers processed material at a high rate for the operator

- Distribute – the high speed fan can be connected to various delivery systems, eg,127mm (5″) diameter pipe/manifold

MARTIN PEARS ENGINEERING BUILDING FOR BUSINESS EXPANSION

MARTIN PEARS ENGINEERING BUILDING FOR BUSINESS EXPANSION